|

Steel |

|

||||||

Vacuum pipesThe cold bore tubes of the dipole magnets are seamless non-magnetic austenitic steel tubes 15.6 m long. The insulated cold bore tubes are placed in the aperture of the coils and form part of the inner wall of the helium vessel that contains the active part of the magnet. The cold bore tube is the passage for the circulating particle beams and as such, the tube wall separates the helium volume from the beam vacuum. Main characteristics of the bare cold bore tubes for the main

LHC dipoles & SSS Beam screen which sits inside the cold bore tubes: The manufacturing process

starts by co-laminating a specially developed low permeability 1mm thick austenitic

stainless steel strip with a 75 µm copper sheet and rolling

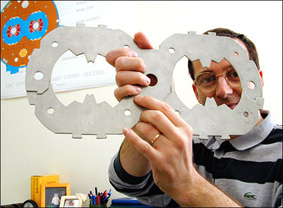

a saw-tooth structure which will Full details in chapter 12 of the LHC design report: MagnetsThe manufacture of the coils, which contain the superconducting cable to provide the all-important 8.33 T magnetic field, represents 60% of the magnet production work. The niobium-titanium coils create the magnetic fields to guide the two counter-rotating proton beams in separate magnetic channels, but within the same physical structure. The coils are surrounded by non-magnetic "collars" of austenitic steel, a material that combines the required properties of good thermal contraction and magnetic permeability. The collars hold the coils in place against the strong magnetic forces that arise when the coils are at full field - the force loading 1 m of dipole is about 400 tonnes. 12 million steel collars for the LHC main magnets.

|

||||||||